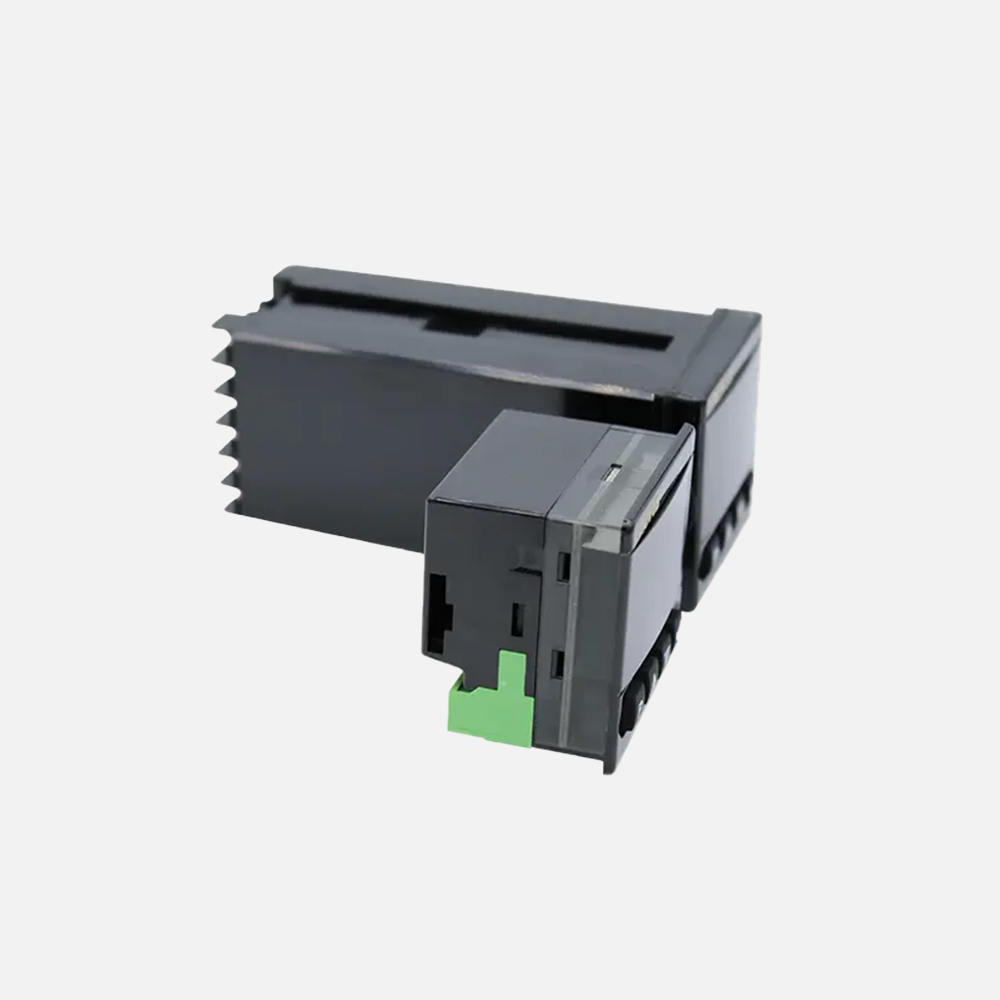

Compact, Precise, and Efficient

For industrial operations that need accurate and dependable temperature management, the N1030 Industrial Temperature Controller is the best option. It is small, effective, and provides quick reaction, easy configuration, and automatic PID adjustment, which guarantees energy savings and thermal stability. The N1030’s detachable connector makes it simple to install and enables a 20-second setup, which streamlines production and minimizes downtime.

What is the operation of an industrial temperature controller?

An industrial temperature controller uses information from sensors like Pt100, J, K, and T thermocouples to measure and control temperature. With PID control for increased precision, the N1030 automatically modifies the heating or cooling system to maintain the temperature within the specified range.

Benefits and advantages of the N1030 Temperature Controller

• High accuracy, with precision up to 0.25%.

• Flexible outputs, including SSR pulse and relay options.

• CE and UL certifications, ensuring safety and compliance.

• Password protection, to prevent unauthorized adjustments.

• Compact dimensions, ideal for small panels.

• Simple and intuitive configuration, minimizing installation time.

How to choose the ideal Temperature Controller for your company

When selecting an industrial temperature controller, consider factors such as:

• The type of sensor to be used.

• The required temperature range for the process.

• The need for PID or On/Off control.

• The type of output (relay or SSR pulse) for load activation.

The N1030 stands out for its versatility, offering efficient solutions for various industrial applications.

Temperature controllers’ advantages in industrial automation

Maintaining the effectiveness and quality of industrial processes while lowering waste and failure rates requires precise temperature management. More dependable and regular operations are encouraged by the N1030’s stable and continuous temperature adjustment.

How to ensure energy efficiency with the N1030 Industrial Temperature Controller?

The N1030 is designed to optimize energy consumption, avoiding unnecessary thermal fluctuations and contributing to resource savings, ensuring efficient performance and operational cost reduction.

Comparison: Analog vs. Digital Industrial Temperature Controllers

• Analog controllers: Require manual adjustments, offer lower precision, and are recommended for simple applications.

• Digital controllers: Provide more precise control, automatic adjustment, and additional functions for higher efficiency.

As a digital controller, the N1030 offers a robust and reliable solution for complex industrial applications.

Recommended applications for the N1030 Industrial Temperature Controller

This controller is ideal for use in various industrial applications, including:

• Refrigeration and heating equipment.

• Manufacturing processes in the food and pharmaceutical industries.

• Thermal control in small industrial machines.

Trends in Industrial Temperature Controllers

With the growing need for efficiency and precision in industrial processes, temperature controllers are evolving to offer:

• Higher accuracy and reduced response time.

• Increasingly intuitive interfaces for easier operation.

• More compact designs adaptable to various industrial environments.